Above-ground storage tanks for the storage of strategic oil reserves, underground pipelines and filling station areas are among the main types of equipment that we protect against corrosion. The primary protection consists of special long-life coating systems for above-ground parts and insulating coatings (bitumen, polyethylene) for underground lines. Cathodic protection, where the insulation of the oil pipeline or the tank bottom could be damaged, acts as a secondary measure. This system is made up of a network of cathodic protection stations for several providers who lead their oil pipelines through a common corridor. Cathodic protection uses simple electro-chemical processes to protect underground parts in places of possible insulation failure.

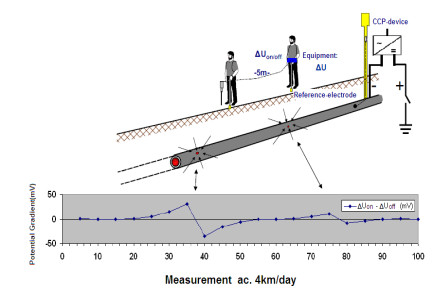

The functionality of the cathodic protection is verified by remote transmission from individual stations, by 24/7 registration measurements using a Korodat system, and also in the field by regular quarterly measurements on interconnecting objects. The integrity of the pipe insulation is tested at regular intervals by inspecting the insulation and any defects found are evaluated and included in the repair plan.

The quality and residual life of the coating systems of tanks or above-ground parts of pipelines is continuously evaluated by qualified internal and external supervisors according to valid standards. Storage tanks are units with a large area of thousands of square meters. It is a logistical challenge to maintain them in good condition.

Corrosion protection is performed in cooperation with other specialists within the Inspection and Quality Department. Modern hardware and software resources, and in particular a geographic information system, are used for data storage and evaluation.